Polymer Raw Materials

Witness Samples & Blanks

Apollo Optical Systems is the world leader in Polymer Optics. As such, we understand the necessity for high quality raw materials during the prototyping and manufacturing processes. A common option for manufacturing prototype polymer optics is to single point diamond turn (SPDT) them.

Witness Samples

Standard 25.4 mm x 1.5 mm round witness samples are available for use in coating runs. Using the same material as the optics ensures that measurement of the optical coating matches the performance of the lenses. Most coaters use fused silica witness samples and adjust the results to show the optical performance with the polymer optic. Make sure your coater uses the same witness sample material as your optic!

Witness Samples

| Diameter (mm) | 25.4 |

| Thickness (mm) | 1.5 |

| Minimum Order Quantity | 100 |

| MATERIAL | PART NUMBER |

|---|---|

| PMMA | 23-0128 |

| Polycarbonate | 23-0129 |

| Polystyrene | 23-0130 |

| COP (Zeonex K22) | 23-0131 |

| COP (Zeonex K26) | 23-0132 |

| COP (Zeonex T62) | 23-0133 |

| COC (APEL XH) | 23-0134 |

| ULTEM | 23-0135 |

Blanks / Pucks

Diamond turned polymer optics require the polymer raw material to be molded and/or annealed to match the material properties of an injection molded optic. Apollo Optical Systems’ Diamond Turning Blanks have been molded under the same processes as optics that are injection molded from the same material. This ensures identical performance between the prototype stage and production.

Blanks / Pucks are available unannealed or annealed. Stress measurements can be provided upon request.

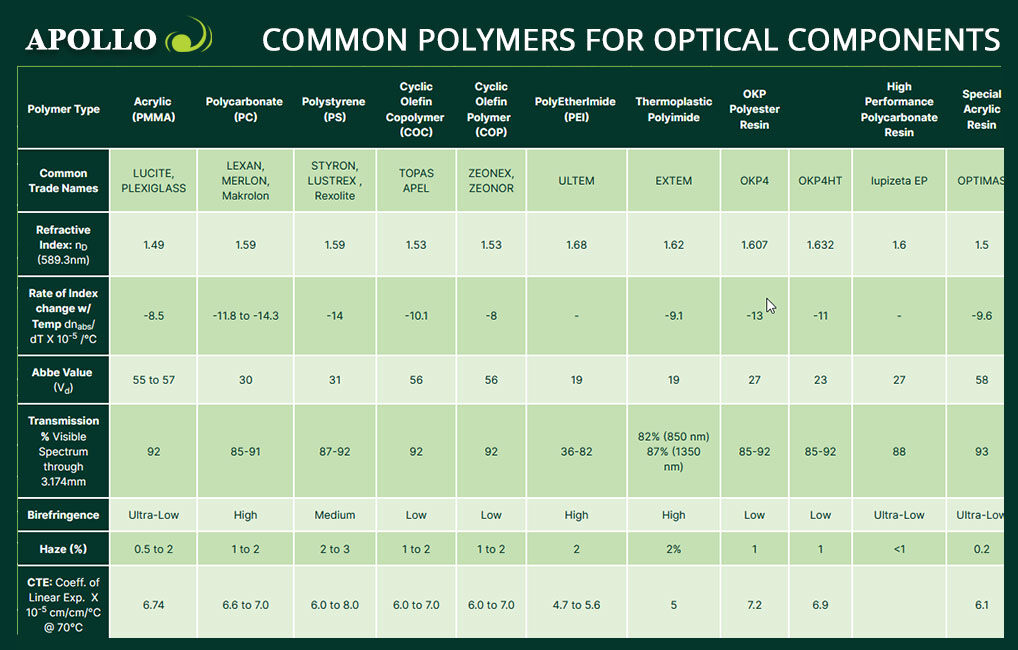

Common Materials Available for use in Diamond Turning Blanks & Witness Samples

- PMMA

- Polycarbonate

- Polystyrene

- ZEONEX (COP) K22R, K26, T62

- APEL (COC) XH

- ULTEM 1000